Sailcloth is the fabric used to make sails for boats and yachts. It’s crucial for optimizing sailing performance and durability. The specific yarn sizes used in sailcloth significantly impact its performance and durability, making it essential to match the right yarn sizes with desired sail attributes. Different materials and constructions of sailcloth cater to varying sailing needs, from leisure to competitive racing. This guide will cover the evolution, types, and innovations of sailcloth, helping you choose the right material for your sailing needs.

Key Takeaways

-

The evolution of sailcloth materials has transitioned from natural fibers to synthetic materials, significantly enhancing durability and sailing performance.

-

Laminated sailcloth, particularly with construction methods like film-scrim-film and woven-film-scrim-film-woven, offers superior strength and reduced stretch, critical for maintaining sail shape.

-

Modern sailcloth predominantly utilizes synthetic fibers like polyester, aramid, and liquid crystal polymers, which provide improved resistance to environmental factors and performance for both recreational and competitive sailing.

Understanding Sailcloth

Sailcloth is a critical component of a sail, providing the necessary strength, durability, and stability to withstand the harsh marine environment. Understanding sailcloth is essential for sailors, as it can significantly impact the performance and longevity of their sails. Sailcloth is made from various materials, each with its unique characteristics, advantages, and disadvantages. By understanding the different types of sail materials, sailors can make informed decisions when selecting the right sailcloth for their needs.

Evolution of Sailcloth Materials

The history of sailcloth materials is a fascinating journey that mirrors the advancements in technology and the evolving needs of sailors. Traditionally, sails were crafted from natural fibers such as flax and cotton canvas. These materials, while sturdy, had limitations in terms of durability and performance. Woolen sails were also popular in Scandinavian, Scottish, and Icelandic cultures from the 11th to the 19th centuries, showcasing the diverse approaches to sail making across different regions.

The late 20th century marked a significant shift in sailcloth manufacturing with the introduction of synthetic materials. These new materials began to replace natural fibers, bringing about a revolution in the sailmaking industry. Synthetic fibers offered enhanced durability, reduced stretch, and greater resistance to environmental factors, making them ideal for modern sailing.

Advancements in sailcloth technology have not only improved the materials but also the construction methods, leading to sails that are lighter, stronger, and more efficient. These technological strides have significantly enhanced sailing capabilities, allowing for better performance and durability on the water.

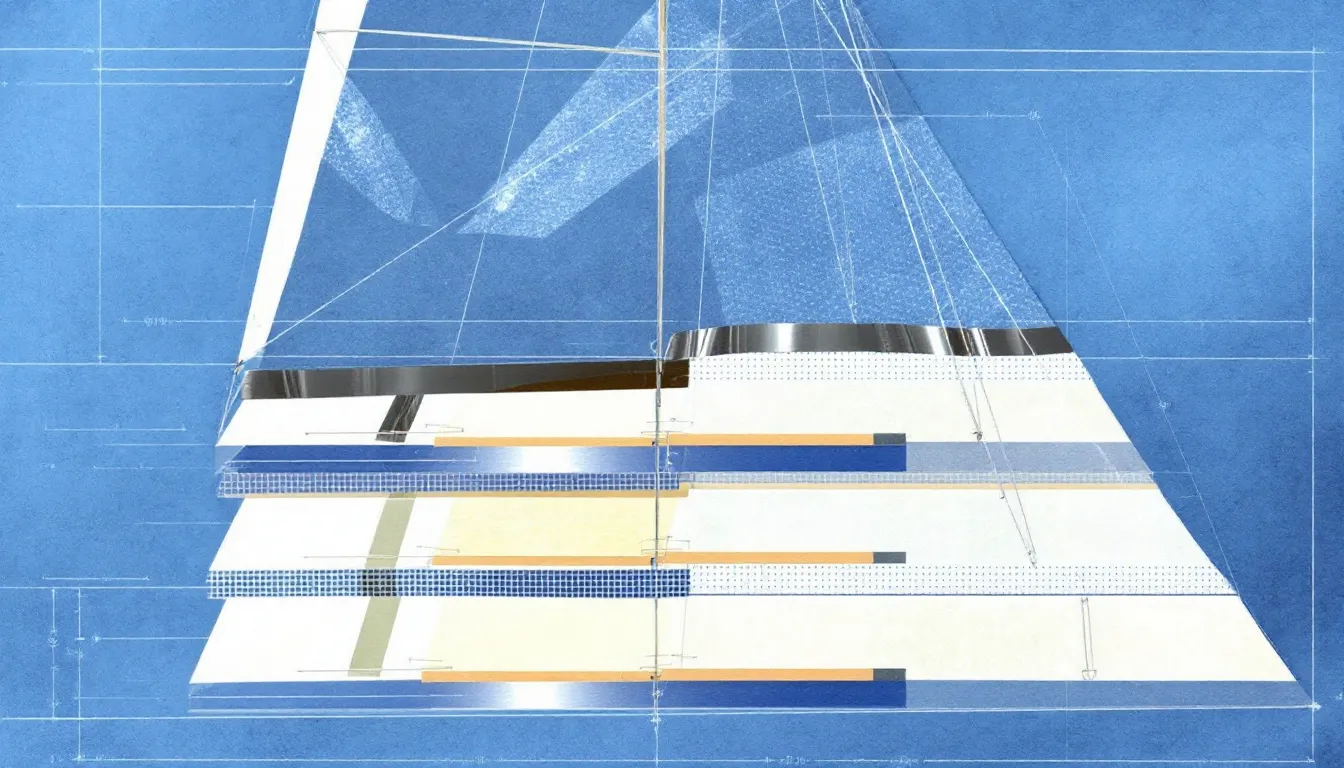

Laminated Sailcloth Explained

Laminated sailcloth represents a significant advancement in sail material technology. Different yarn sizes are used in laminated sailcloth to optimize strength and performance. This construction method involves layering multiple materials with distinct characteristics to create a composite fabric with superior performance. The lamination process allows fibers to be placed in straight, uninterrupted paths, which enhances the strength and performance of the sail.

One of the primary benefits of laminated sailcloth is its reduced stretch in all directions, which is crucial for maintaining sail shape and performance. Minimizing stretch allows laminated sails to maintain their optimal shape, enhancing aerodynamics and efficiency on the water. This construction method is particularly popular among competitive sailors who demand the highest levels of performance from their sails.

Film-Scrim-Film Construction

The film-scrim-film construction method is a prime example of how laminated sailcloth can enhance sail performance. This technique involves sandwiching strands between layers of film, maximizing the strength of the fibers. The film layers provide most of the stretch resistance, ensuring that the sail maintains its shape under various conditions.

High-end film-scrim-film constructions often incorporate advanced materials such as woven Spectra or Kevlar, further enhancing the sail’s performance. However, this method has its drawbacks, such as less abrasion and flex resistance compared to woven fabrics, and it does not protect fibers from UV exposure.

Woven-Film-Scrim-Film-Woven Method

The woven-film-scrim-film-woven method is another innovative approach to sailcloth construction. This technique is characterized by its high UV and abrasion protection, making it suitable for various sailing conditions. By incorporating high modulus fibers, this method maximizes strength and durability while reducing the amount of adhesive needed.

Although more experimental than practical, the woven-film-scrim-film-woven method offers significant benefits in terms of performance and protection. The strong bond created by this construction technique ensures that the sail can withstand the rigors of competitive sailing.

Types of Synthetic Fibers in Sailcloth

Modern sailcloth is predominantly made from synthetic fibers, which have revolutionized the sailing industry. Materials such as nylon, Dacron, and aramid fibers like Kevlar are commonly used to enhance the performance and durability of sails. These synthetic fibers offer distinct advantages over traditional natural fibers, providing greater resistance to tearing, abrasion, and environmental factors.

The transition to synthetic materials began in the late 20th century and has since become the standard in sailmaking. Sailcloth manufacturers continually innovate to develop materials that meet the demanding needs of both recreational and competitive sailors.

Polyester (PET)

Polyester, also known as PET, is a popular choice for sailcloth due to its affordability and resilience. Polyester sailcloth is favored for its good strength, cost-effectiveness, and resistance to UV damage, making it suitable for a broad range of sailing environments. This balance of affordability and performance makes polyester a top choice among recreational sailors.

Polyester’s resistance to UV exposure and durability over time have made it a staple in sailcloth manufacturing. Its durability ensures that sails made from polyester can endure the harsh conditions of the marine environment.

Aramid Fibers (Kevlar)

Aramid fibers, commonly known as Kevlar, are highly valued in sailcloth for their exceptional strength and minimal stretch properties. These characteristics make Kevlar an ideal material for high-performance sails, where maintaining shape and performance under various conditions is crucial.

However, aramid fibers can be susceptible to UV damage, necessitating protective measures such as the film-scrim-film construction method to enhance their UV resistance. Despite this vulnerability, the strength and durability of aramid fibers make them a preferred choice for racing sails.

Liquid Crystal Polymer (LCP)

Liquid Crystal Polymer (LCP) fibers are renowned for their impressive strength and stability, making them ideal for high-performance racing applications. LCP fibers maintain superior stability and strength even in extreme sailing conditions, ensuring that sails perform optimally under pressure.

These fibers also provide excellent UV protection, which is crucial for maintaining their integrity over time. The remarkable strength and stability of LCP fibers make them a top choice for competitive sailors seeking the best performance from their sails.

Types of Sail Materials

There are several types of sail materials available, each with its own strengths and weaknesses. Polyester is a popular choice for sailcloth due to its strength, durability, and relatively low cost. Nylon is another common material used for sailcloth, particularly for spinnakers and asymmetric spinnakers, due to its lightweight strength and good UV stability. Aramid fibers, such as Kevlar and Twaron, are often used in racing sails due to their high resistance to stretch and high breaking strength. Ultra PE fibers, such as Dyneema, offer excellent UV resistance, low stretch, and high breaking strength, making them ideal for high-performance sails.

Specialized Sailcloth for Racing

Specialized sailcloth is essential for racing, where performance and efficiency are paramount. Aramid fibers, such as Kevlar, are preferred for racing sails due to their combination of lightweight, high strength, and minimal stretch. Selecting the right yarn sizes can enhance the performance and durability of racing sails by matching the desired attributes such as strength and stretch to the specific sailing conditions. These attributes ensure that racing sails can maintain their shape and performance under the intense conditions of competitive sailing.

LCP fibers are also highly regarded for their strength and stability, making them ideal for high-performance racing sails. The weight of the sailcloth plays a significant role in performance, with lighter fabrics generally offering better speed and responsiveness.

Warp Drive

Warp Drive sailcloth employs a unique radial construction, which effectively distributes loads across the sail, thereby minimizing stretch. This enhanced load distribution results in greater efficiency in sail performance under various wind conditions.

The radial construction of Warp Drive sailcloth allows for more even load distribution compared to traditional designs, translating to better shape retention and predictable handling while sailing.

Fibremax

Fibremax combines robust strength with exceptional durability, making it suitable for both high-performance racing and cruising applications. This fiber sailcloth balances performance and endurance, crucial for sailors seeking reliability in diverse conditions.

Fibremax sailcloth is engineered to balance exceptional strength with durability, making it ideal for both racing and cruising applications. Its blend of performance and longevity ensures that it can withstand the demands of competitive sailing while providing reliable performance for cruising.

High-Performance Sail Materials

High-performance sail materials are designed to provide exceptional strength, durability, and stability. Liquid crystal polymer (LCP) fibers, such as Vectran, offer excellent stretch and flex resistance, making them suitable for high-performance sails. PEN fibers, such as Pentex, are related to polyester but stretch about half as much, making them ideal for class and rating rule-restricted applications. Carbon fibers are impervious to UV damage and have extremely high modulus (low stretch), making them suitable for grand prix sailing and high-end cruising applications.

Spinnaker Sailcloth Characteristics

Spinnaker sailcloth is typically made from lightweight nylon that provides exceptional strength. This type of sailcloth features a melamine finish, which contributes to its zero-porosity characteristic, ensuring optimal shape and performance.

Different yarn sizes impact the strength and performance of spinnaker sailcloth, with finer yarns offering more flexibility and coarser yarns providing greater durability.

The construction of spinnaker fabric often includes a ripstop design, enhancing its tear resistance. The lightweight, urethane-coated RipStop nylon used in spinnaker sailcloth ensures minimal weight while maintaining strength, making it ideal for racing sails.

Sailcloth Construction and Weight

Sailcloth construction and weight are critical factors to consider when selecting a sail material. Sailcloth can be constructed using various methods, including laminating multiple materials with different characteristics to synergize their qualities. Lamination allows fibers to be placed in a straight, uninterrupted path, maximizing their strength and stability. Sailcloth weight is also an important consideration, as lighter sails can improve performance and reduce fatigue. However, lighter sails may not be as durable as heavier sails, and may require more frequent replacement.

Factors Influencing Sailcloth Choice

Choosing the right sailcloth involves considering various factors, including the sailing conditions, budget, and performance needs. Synthetic fibers used in sailcloth vary in properties, influencing choice based on durability, low weight, and resistance to environmental factors. The intended use of the sail, whether for cruising or racing, plays a vital role in selecting the appropriate sailcloth to meet performance requirements.

UV exposure is a critical factor in sailcloth selection, as prolonged sunlight can degrade materials. Effective UV protection includes using covers and strips on sails, which should be checked regularly for proper fit and condition. Signs of UV damage may include thread failure in stitching and colour fading, particularly in reds and yellows and other colours.

Regular inspections for stitching integrity are vital, as weakened stitching can compromise the sail’s overall strength. Ensuring that the sailcloth meets the specific demands of your sailing activities will help you achieve the best performance and longevity.

Choosing the Right Sailcloth

Choosing the right sailcloth depends on several factors, including the intended use of the sail, the sailor’s budget, and personal preferences. Sailors should consider the type of sailing they will be doing, the size and type of their boat, and the level of performance they require. They should also consider the durability and maintenance requirements of the sailcloth, as well as its resistance to UV exposure, abrasion, and other environmental factors. By carefully evaluating these factors, sailors can select the right sailcloth for their needs and ensure optimal performance and longevity.

Maintenance and Care for Sailcloth

Proper maintenance and care are essential for prolonging the life of sailcloth materials. To ensure your sails remain in top condition, it’s crucial to wash or rinse them to eliminate salt and dirt after each use. Storing sails in dry, protected conditions is essential, as damp or extreme environments can lead to premature deterioration.

Additionally, protecting sailcloth from ultraviolet light and flexing is necessary to maintain its integrity over time. Regular inspections and timely repairs can significantly extend the lifespan of your sails, ensuring they perform optimally during your sailing adventures.

Innovations in Sailcloth Technology

Recent innovations in sailcloth technology have further enhanced the performance and durability of modern sails. AEROTECH, developed by North Sails, is a groundbreaking new woven sailcloth aimed at enhancing downwind performance. This technology addresses the performance limitations of traditional materials, providing greater durability and shape retention under dynamic sailing conditions.

North Sails has also developed North Panel Laminate (NPL) using advanced machines specifically designed for sailcloth laminating. These innovations ensure minimal stretch and optimal load distribution, maintaining the sail’s shape and performance during competitive sailing.

Summary

The evolution of sailcloth materials has significantly impacted the sailing industry, from traditional natural fibers to advanced synthetic materials. Understanding the different types of sailcloth, their construction methods, and their specific uses can help sailors make informed choices for their needs. Proper maintenance and care further ensure the longevity and performance of these high-tech fabrics.

As sailcloth technology continues to advance, the possibilities for enhancing sailing performance are boundless. Embracing these innovations can lead to more efficient and enjoyable sailing experiences, whether for recreational cruising or competitive racing.

Frequently Asked Questions

What are the traditional materials used for making sails?

The traditional materials used for making sails predominantly comprise natural fibers such as flax and cotton canvas, along with wool, which has been employed in various cultures. These materials have proven effective for sail construction throughout history.

What are the benefits of laminated sailcloth?

Laminated sailcloth significantly improves strength and minimizes stretch, which helps maintain optimal sail shape and enhances performance. This results in a more efficient and durable sailing experience.

Why is polyester a popular choice for sailcloth?

Polyester's affordability, resilience, and resistance to UV damage make it an ideal choice for sailcloth, particularly for recreational sailors seeking durability and cost-effectiveness.

What makes aramid fibers suitable for racing sails?

Aramid fibers, such as Kevlar, are suitable for racing sails due to their exceptional strength and minimal stretch, ensuring optimal performance under high-stress conditions. This combination enhances the durability and efficiency of racing sails significantly.

How can sailors maintain their sails to prolong their lifespan?

Sailors can prolong the lifespan of their sails by regularly washing or rinsing them after use, storing them in dry conditions, and protecting them from UV light. These practices are essential for maintaining sail integrity and performance.